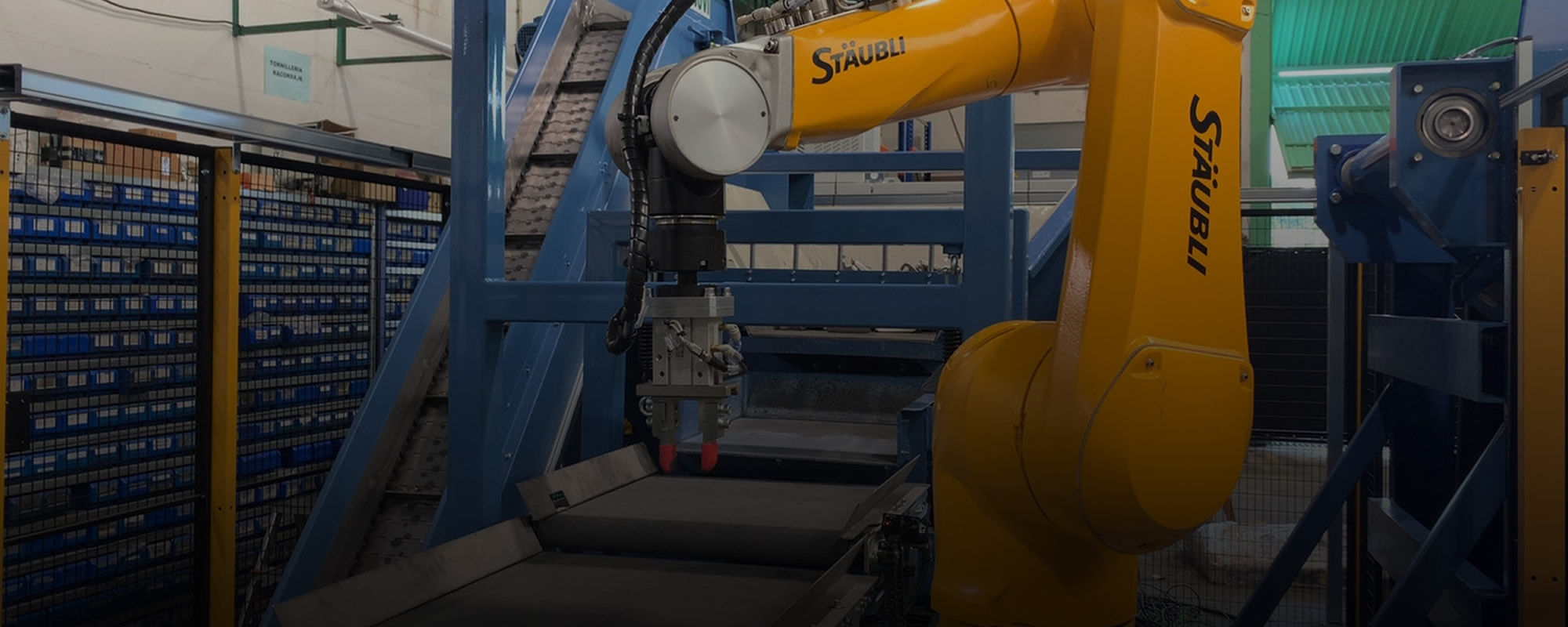

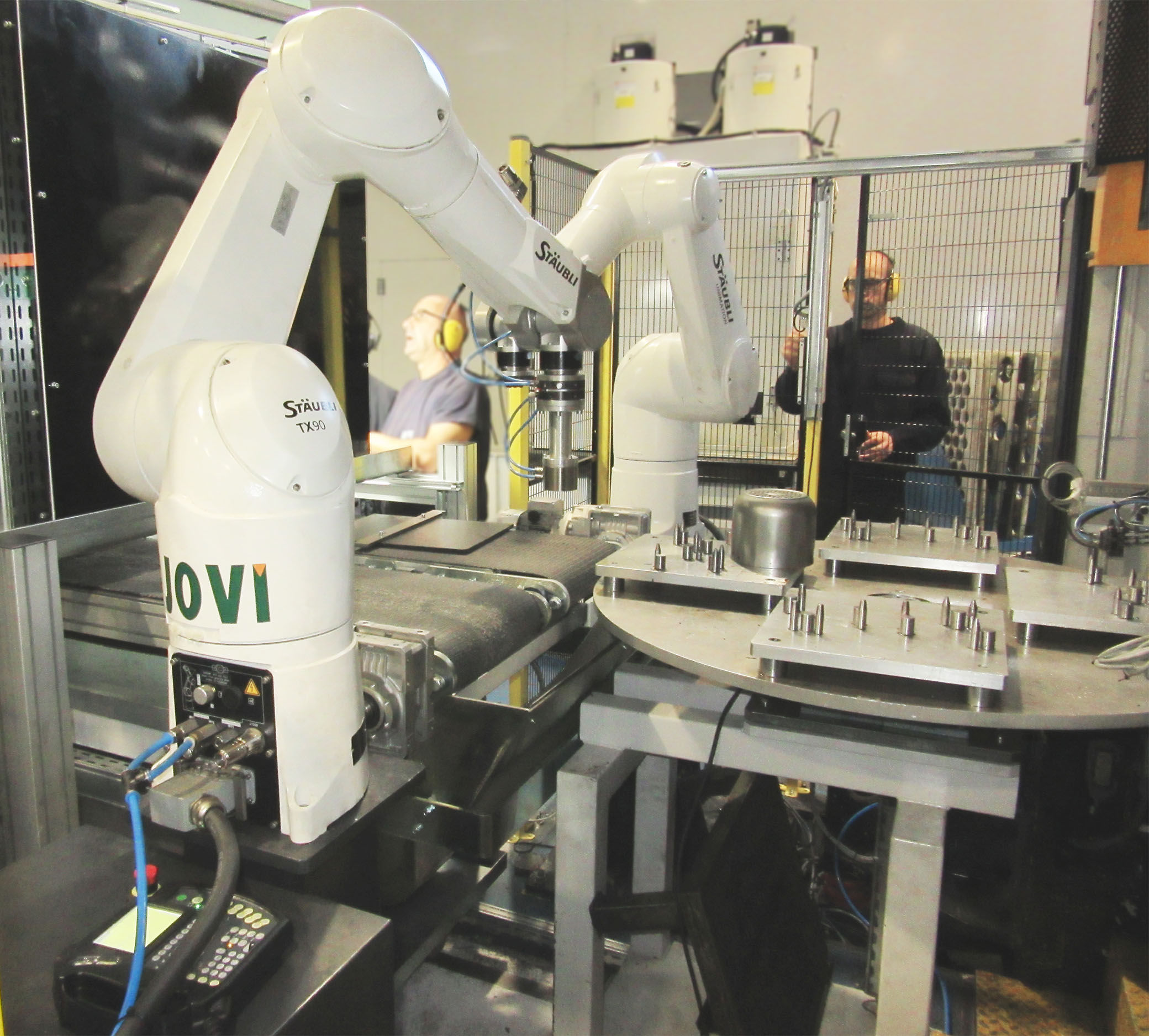

Bespoke dosing and manipulation solutions

We devise and develop a bespoke solution in line with the needs of each project.

Experience

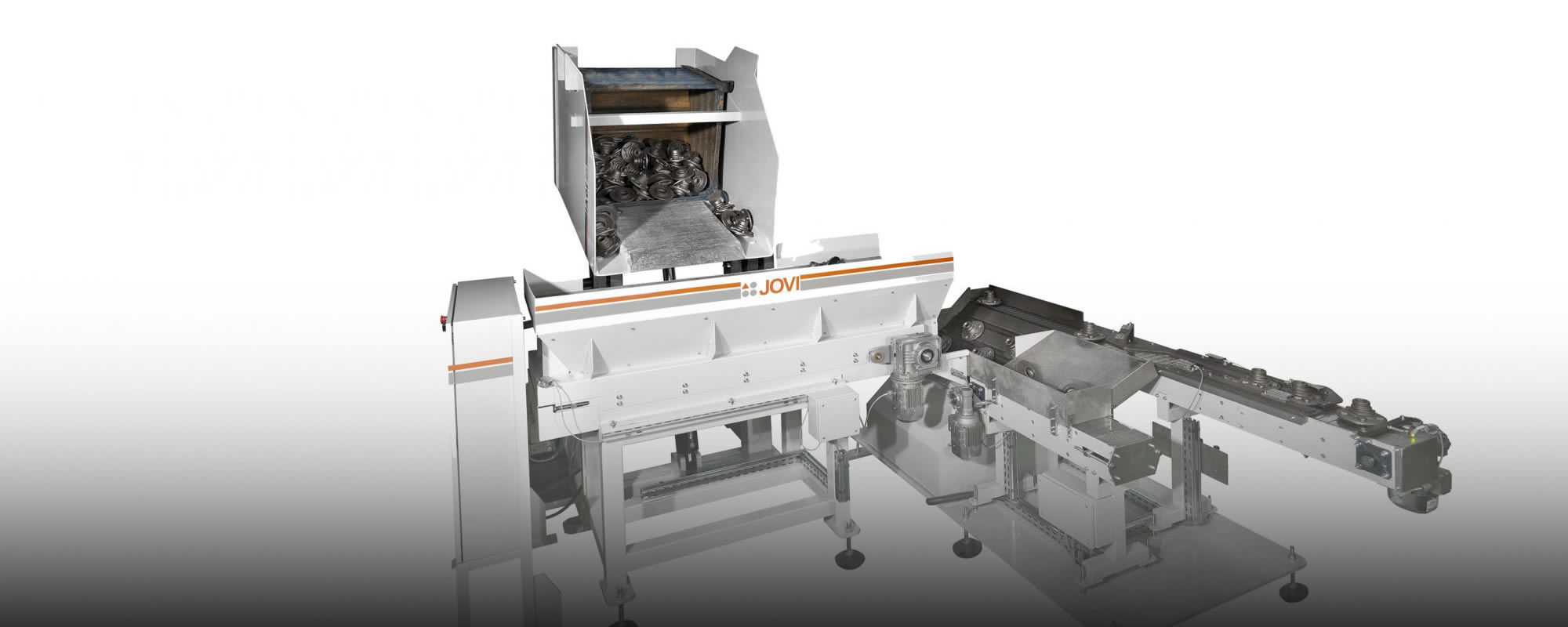

Feeder and positioning systems

We take an input of bulk parts, separating and positioning them to be prepared for the next process.

Experience

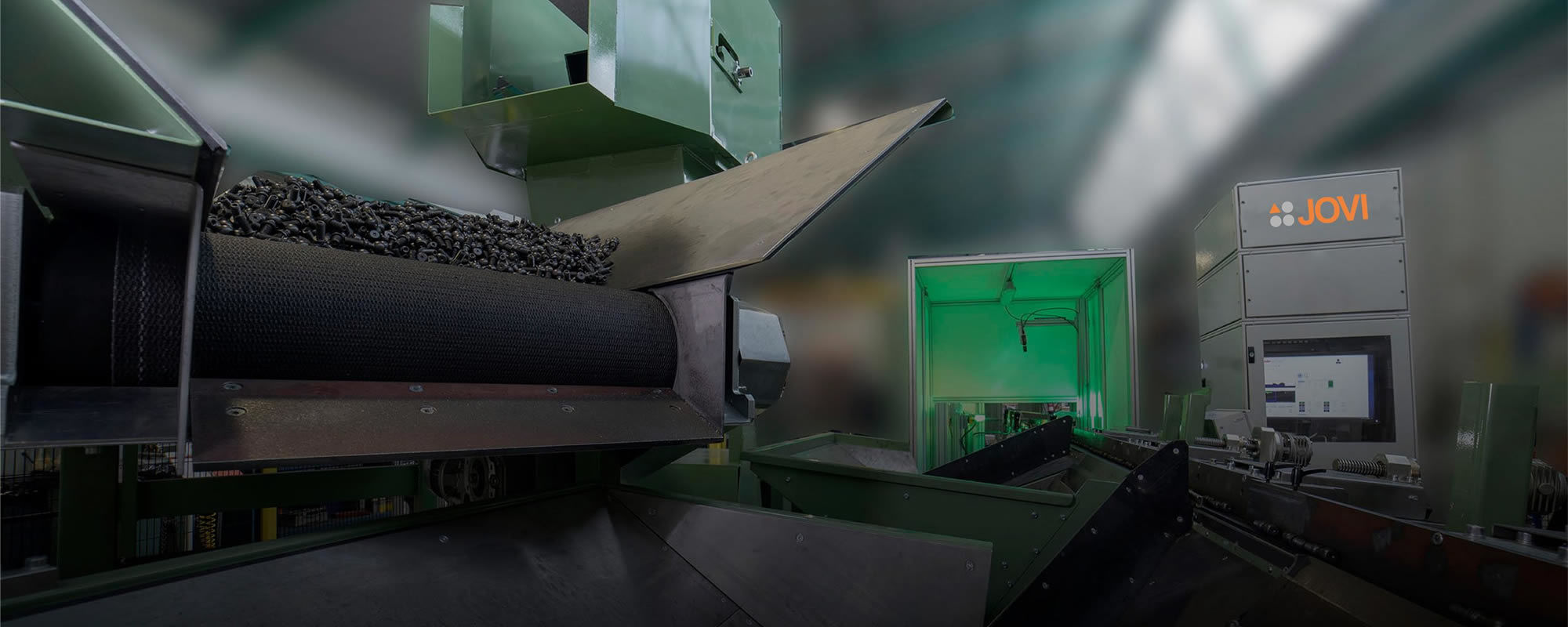

Experts in dosing of parts for machine vision control processes

We perform the part positioning step for the vision control process.

About us

We take an input of bulk parts, separating and positioning them to be prepared for the next process

We develop automation systems in close collaboration with our clients through simultaneous engineering.

Read more

We are a multidisciplinary professional team

We complement one another to successfully undertake the assigned projects.

About usWe focus on the design and manufacture of automated feeder systems for production processes.

We develop automation systems in close collaboration with our clients through simultaneous engineering, helping to provide them with solutions in the shortest possible timeframe, to increase the competitiveness and quality of their products.

The Jovi workforce comprises a team of more than 25 people.

All processes are performed at JOVI: mechanical and electrical design, manufacturing (CNC machining, metalwork and paintwork), mechanical and electrical assembly, programming and commissioning.

We accompany our clients from start to finish in each project, evaluating the best way of performing the process, and commissioning the equipment wherever required.

At JOVI we work with the leading makes in the sector. We are committed to the highest levels of quality and competitiveness.